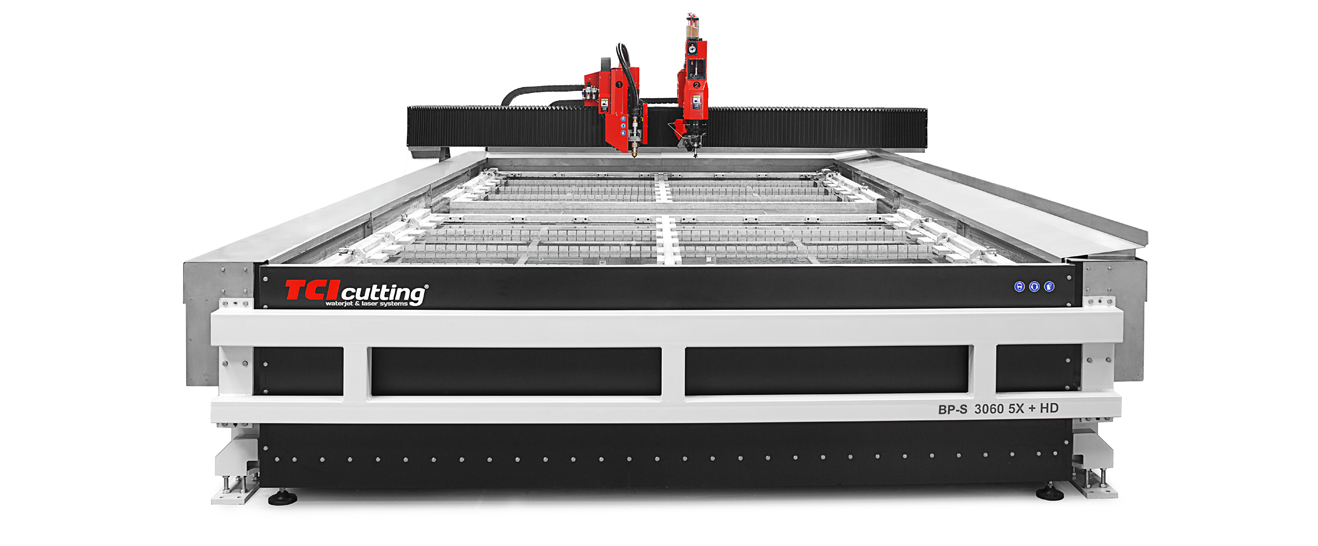

STORE LOGISTIC offers a brand new series of combined cutting machines with water and Plasma.

The combined water and plasma cutting machines series features a unique, compact and stable design.

Flexible and robust combined cutting machines through STORE LOGISTIC.

The versatility of this machine is given by the combination of soft water jet cutting and the faster plasma contour cutting.

The modular architecture of the water and plasma cutting machines simplifies transport and provides customers with more flexibility as it allows future upgrades through the addition of new modules, a new bridge with multiple heads or a second cutting head.

The expansion options for the setup and the adaptation of the water-jet and plasma cutting machine to the customer’s needs, are limitless.

This way, we are ensuring efficiency now, and in the future.

This is the reason why STORE LOGISTIC is offering the water-jet and plasma cutting machines series.

Cutting dimension are:

- Width X=2000/4000 mm

- Length Y=4000/12000

- Height Z=200 mm

This way, we are ensuring efficiency now, and in the future.

This is the reason why STORE LOGISTIC is offering the water-jet and plasma cutting machines series.

Cutting dimension are:

- Width X=2000/4000 mm

- Length Y=4000/12000

- Height Z=200 mm

The water flow which moves at a speed that is three times higher than the speed of sound reaches the necessary level of energy required for producing the micro-erosion. Thus, water-jet cutting can be characterized as a mechanical process.

The physical attributes of the material remain intact after the water-jet cutting process.

Flexible water-jet cutting solution promoted by STORE LOGISTIC

The process of efficient water cutting starts with a pressure of up to 6500 bar that passes through a diamond orifice with an average speed of 800-100 m/sec transforming the potential energy into kinetic energy. The water-jet speed that results from this process is perfectly capable of cutting:

- Paper;

- Fabric;

- Plastics;

- Fibers etc.

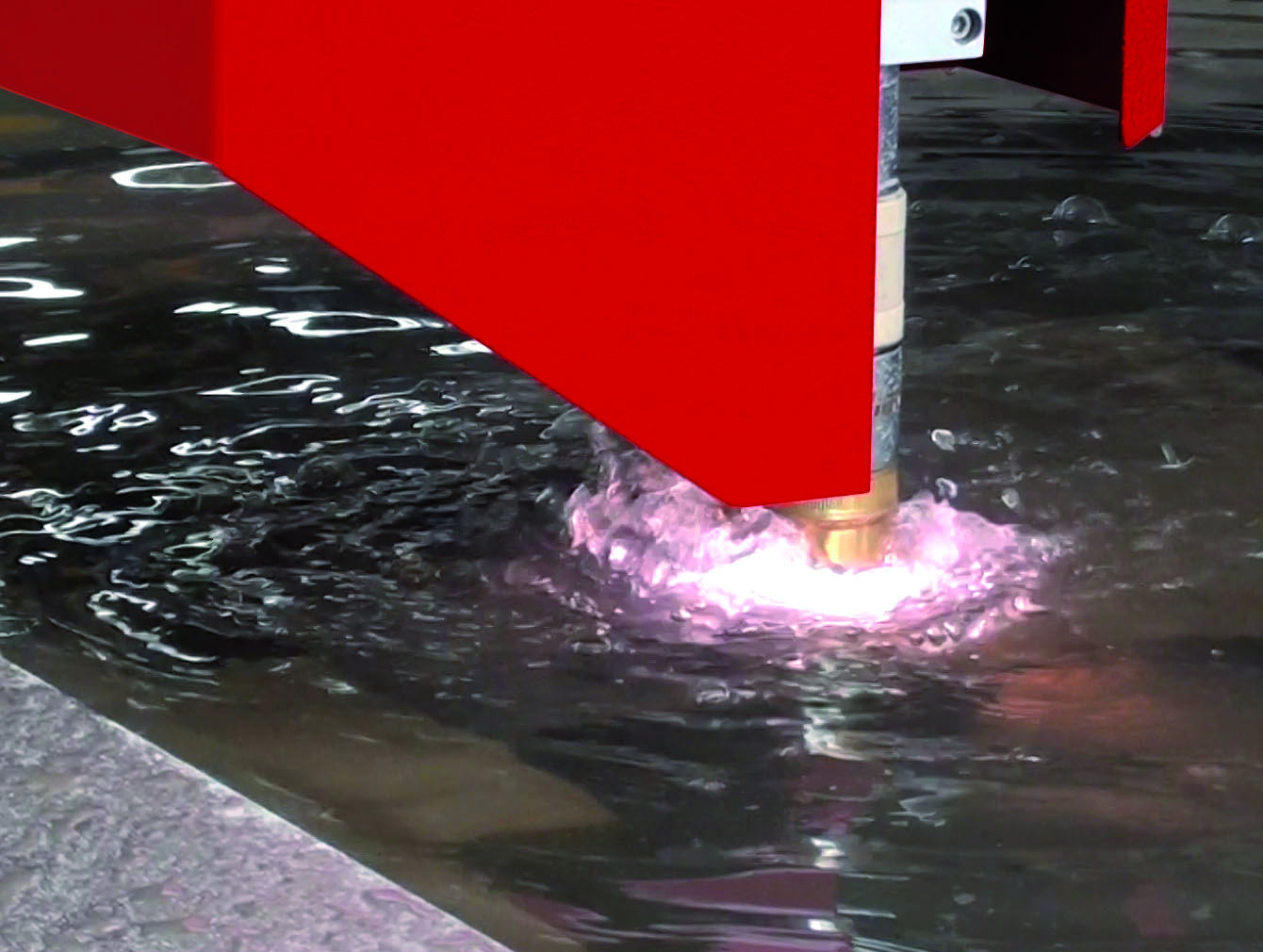

Competitive Plasma cutting machines

This method is utilized in the cutting of steel or other metals of various thicknesses by using a calibrated torque in order to compress the gas that is generated at very high temperatures. The gas is blown at very high speed through a nozzle turning some of it into plasma, which is able to melt and cut metal.

Technical Information:

- Maximum thickness of the part – 200 mm;

- Maximum cutting speed (20 m/min);

- Cutting of materials with thicknesses between 0.5 and 180 mm;

- Repeatability accuracy +- 0.025 mm/m;

- Machine tolerance +- 0.05mm/m.

Applications:

- Industrial and civil constructions

- Sheet metal production

- Naval industry

- Cutting centers for customers

- Windmill production

- Machine tool and vehicle construction

- Railway construction

Features:

- Robust architecture made for heavy duty work;

- Versatile, for combined processes;

- Ease of operation thanks to a 3D system;

- AC Servo Drive system controller;

- Superior accuracy;

- User friendly;

- Material marking options;

- No need for operators during machine runtime.

Română

Română English

English