PUNCHING EQUIPMENT offered by STORE LOGISTIC

CNC punching machines for the sheet metal industry

The compact punching machines promoted by STORE LOGISTIC prove all the advantages of the servo-electric drive concept.

The punching machines are recommended especially for their low energy consumption and reduced noise level during operations.

The punching machine series promoted by STORE LOGISTIC features state-of-the-art servo-electric punching based on its partners’ thirty years of experience.

Dual servo-electric actuation with energy recovery, ultra-high performance.

The energy that is generated during braking is deposited and activated again at the next actuation.

By using a servo-electric drive punching machine, the power consumption can be reduced with up to 50% in comparison to a similar hydraulic machine.

The drive systems, which also contain less components in comparison to a hydraulic system, will reduce maintenance and repair costs.

Runtime errors are totally excluded, scrap is avoided, and costs are minimal.

Compact installation dimensions contributes to efficient production space.

Finished parts are processed without nibble marks with maximum quality.

Benefits

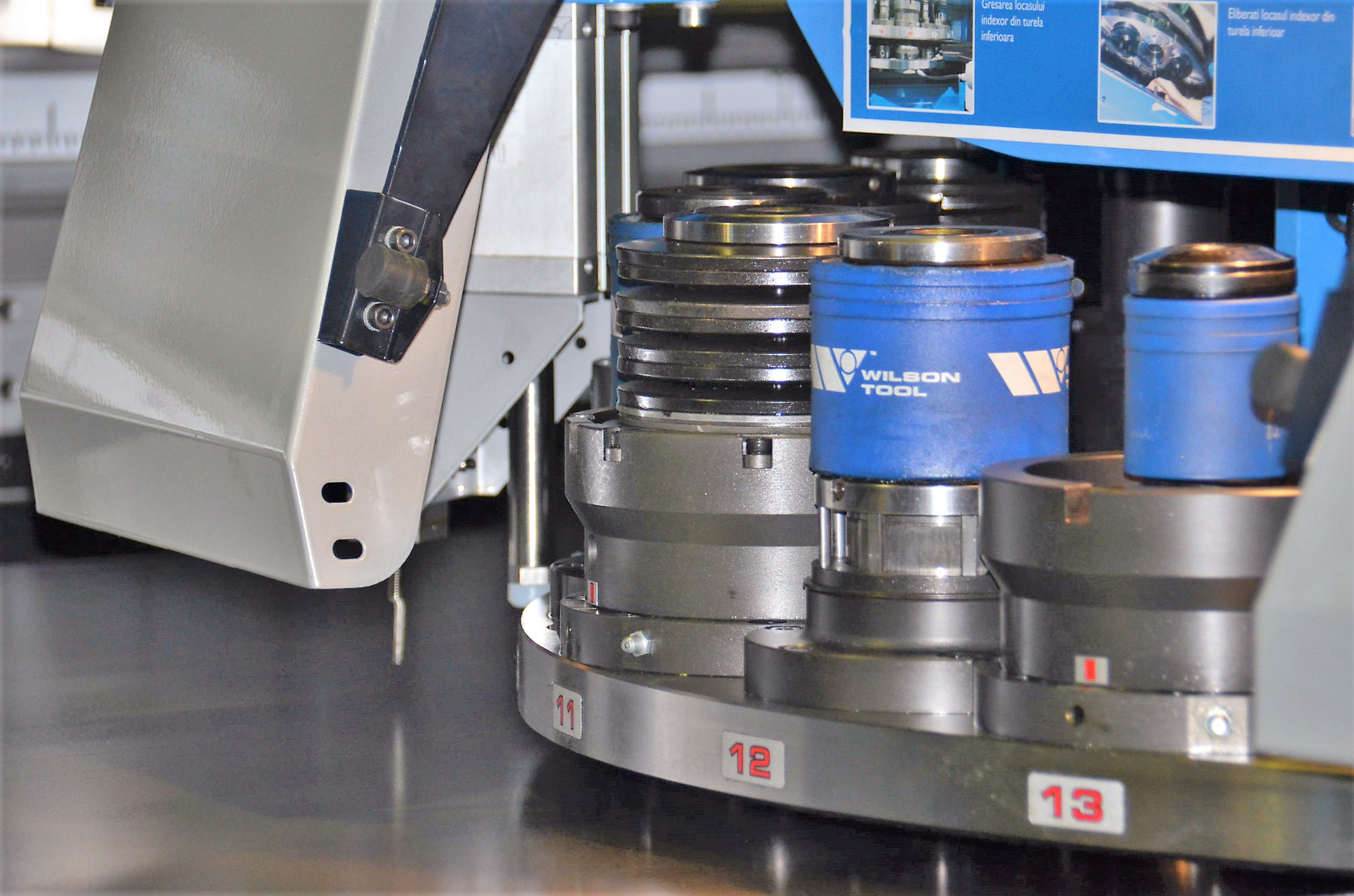

- Flexible turret that is selected in concordance to the needs of the customer

- No dead zones thanks to an individual clamp movement with programmable clamp setting, resulting in 100% sheet utilization

- Robust closed frame for excellent tool system alignment

- Lifting brush tables for an exceptional surface quality and reduced noise level

Technical data

- Sheet size 2500 mm x 1250 mm without repositioning

- Sheet size 3000 mm x 1500 mm

- Sheet size 2500 mm x 1500 mm without repositioning

- Sheet size 4300 mm x 1500 mm

- Sheet size 2500 mm x 1500 mm without repositioning

All models

- Punching speed up to 1800 hpm with 1 mm between holes

- Punching forces – 17/20 or 23/30 tons, up to 8 mm punching capacity

- Tool rotation speed – 133 rpm up to 260 rpm

Leading-edge servo-electric punching

The servo-electric punching process brilliance is apparent from how it merges energy savings with unbeatable accuracy and productivity when compared to the models that are already on the market.

With the ECO series, promoted by STORE LOGISTIC, state-of-the-art servo-electric punching productivity is now accessible.

Impressively accurate forming capabilities through NC-controlled servo-mechanical punching strokes.

This series of punching machines has been developed with the scope of granting flexible and easy to use operations in an affordable package.

STORE LOGISTIC Punching Machines – Features

- 17/20/23/30 tons punching force up to 6-8 mm

- Customizable punching solutions

- Reduced power connection and energy consumption – 3,5 kW – 4 kW

- Automatic clamp setting that positions sheet clamps in concordance to a numerical program

- Customizable turret layout with Standard 45 stations or 250/ 384 tools

- Maximum number of index tools – 128

- Vacuum system

- Scrap conveyors

- Table and wagon automation for: loading, unloading, and stacking

- Wheeling, tapping and upforming with a programmable NC axis

- Work chute (500 mm x 500 mm) and part sorting

Automation

- Intelligent sorting solutions for small work chute parts

- Fast loading/unloading operations with reduced floor space requirements

- Solutions for loading, unloading and stacking of sheets and finished parts

- Access to storage automation systems

Română

Română English

English